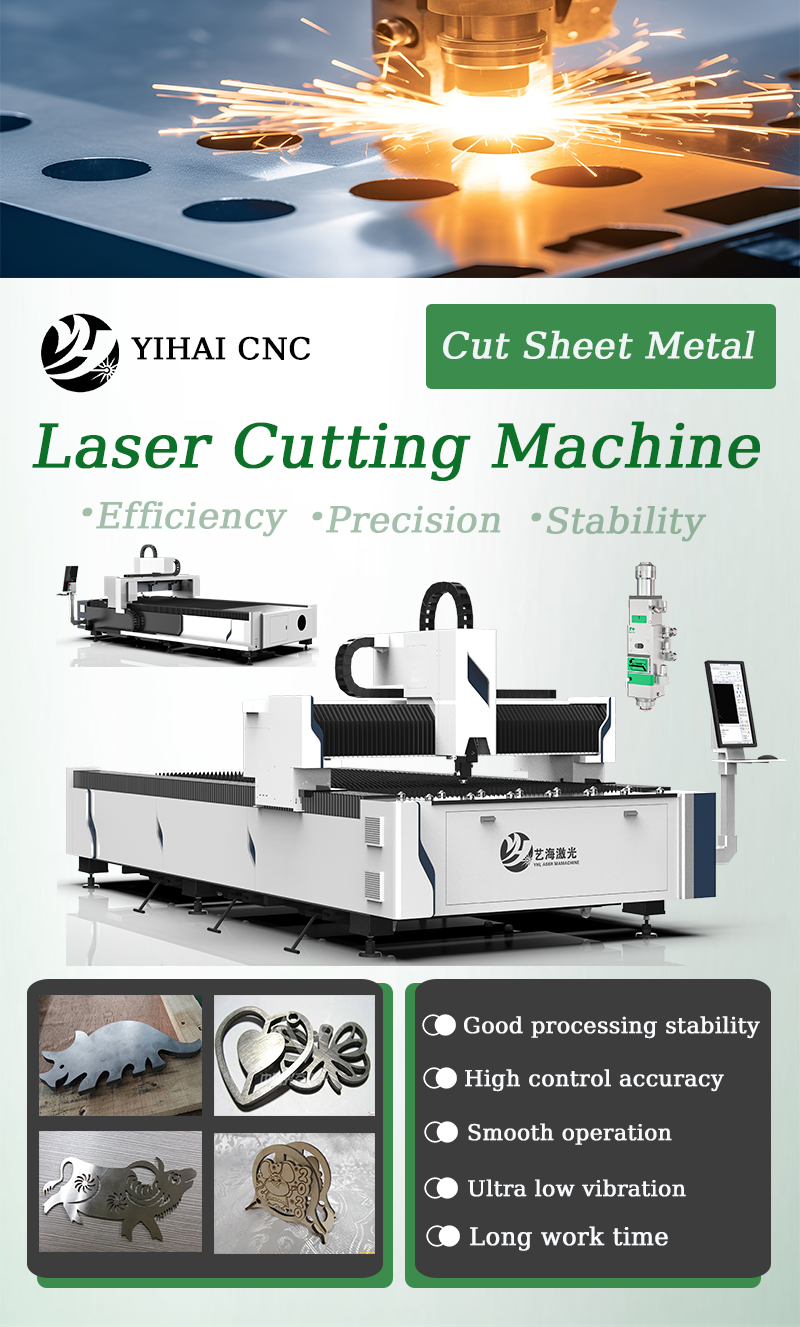

In the realm of precision cutting and manufacturing, laser cutting machines have emerged as a game-changer. These high-tech tools leverage the power of laser beams to cut through a wide range of materials with unparalleled accuracy and efficiency. As the demand for precision in manufacturing continues to grow, laser cutting machines have become indispensable in various industries, from automotive and aerospace to furniture and electronics.

The Evolution of Laser Cutting Technology

The concept of laser cutting dates back to the 1960s when the first laser was invented. Initially, these devices were bulky and expensive, limiting their application to research and military purposes. However, over the decades, advancements in technology have led to the development of more compact, efficient, and cost-effective laser cutting machines. Today, these machines are widely used in various industries due to their versatility, precision, and speed.

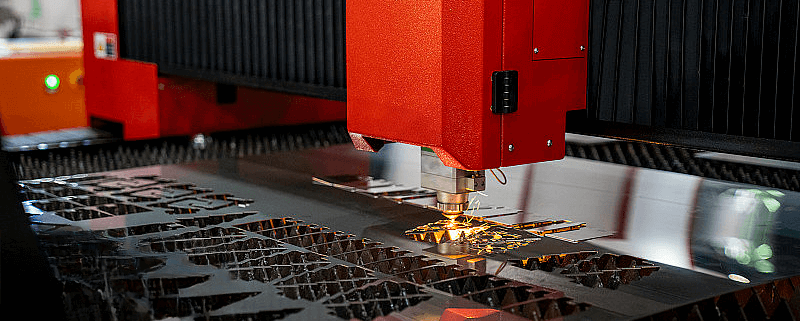

How Laser Cutting Works

Laser cutting involves the use of a high-intensity laser beam to melt or vaporize material, creating a precise cut. The process typically involves three steps:

1、Lasing: A laser diode generates a high-intensity beam of light.

2、Beam Delivery: The beam is directed towards the workpiece through a series of mirrors and lenses.

3、Cutting: The focused beam interacts with the material, causing it to melt or vaporize, resulting in a clean cut.

Benefits of Laser Cutting Machines

1、Precision: Laser cutting machines offer unparalleled precision, with cutting edges that are almost burr-free. This level of accuracy is particularly beneficial in industries that require tight tolerances, such as aerospace and automotive.

2、Versatility: These machines can cut a wide range of materials, including metals (e.g., stainless steel, aluminum), plastics, glass, and even paper.

3、Efficiency: Laser cutting is significantly faster than traditional cutting methods like CNC machining or waterjet cutting, reducing production time and costs.

4、Safety: Since there are no physical contacts between the laser beam and the material being cut, there is minimal risk of operator injury or damage to the machine.

5、Environmental Impact: Laser cutting produces minimal waste and requires no additional cutting fluids or lubricants, making it an environmentally friendly process.

Applications of Laser Cutting Machines

The versatility of laser cutting machines has led to their widespread adoption across various industries:

1、Automotive: Laser cutting is used to create precise parts for engines, transmissions, and other components.

2、Aerospace: In the aerospace industry, laser cutting is employed to manufacture high-precision components for aircraft and spacecraft.

3、Furniture: The ability to cut complex shapes and intricate designs makes laser cutting ideal for the furniture industry.

4、Electronics: In the electronics industry, laser cutting is used to create circuit boards and other precision components.

5、Construction: Laser cutting machines are also used in the construction industry for cutting steel beams and other metal structures.

Future Trends in Laser Cutting Technology

As technology continues to advance, laser cutting machines are becoming more sophisticated and efficient. Some of the key trends to watch out for include:

1、Higher Power Lasers: The development of higher power lasers will enable faster cutting speeds and thicker material capabilities.

2、Automation: Increased automation in laser cutting processes will further reduce human intervention and improve productivity.

3、Integration with Robotics: The integration of robotics with laser cutting machines will lead to more flexible and efficient manufacturing processes.

4、Software Advancements: Improved software algorithms will enable more complex designs and better control over cutting parameters.

5、Sustainability: Efforts to reduce energy consumption and waste during the cutting process will become increasingly important as manufacturers strive for sustainability.

Conclusion

Laser cutting machines have revolutionized the manufacturing industry by providing a precise, efficient, and versatile solution for cutting a wide range of materials. With ongoing advancements in technology, these machines are poised to play an even more significant role in the future of manufacturing. Whether it's in the aerospace industry or furniture manufacturing, laser cutting machines are here to stay and will continue to shape the way we produce goods with precision and efficiency. As we move towards a more connected and automated world, laser cutting technology will undoubtedly play a crucial role in transforming the manufacturing landscape for generations to come.

介绍评测

| 发布日期 | 2024-03 |

| 游戏评分 | 8 |

| 视频评分 | 1 |

| 数码品牌 | 飞利浦(Philips) |

| 销量数量 | 6948080909 |

| 人气 | 6987662162 |

2.数码知识推荐

| 1 | 澳门香港一肖一码一中一特免费公开 |

| 2 | 4887王中王管家婆客服电话 |

| 3 | 新2o24年澳门天天开好彩 |

| 4 | 香港2024最准马资料免费 |

| 5 | 澳门开码表 |

| 6 | 2023澳门特马今晚资料大全 |

| 7 | 2024澳门资料大全免费 |

| 8 | 2O24年澳门今晚开奖号码 |

| 9 | 2024年新澳门天天彩正版免费 |

| 10 | 澳门一肖一码100准确最准一 |

3.详情介绍

| 序号 | 品牌 | 类型 |

| 1 | 联想(Lenovo) | 办公类 |

| 2 | 贝尔金(Belkin) | 通信类 |

| 3 | 希捷(Seagate) | 消费类 |

| 4 | 奥林巴斯(Olympus) | 车载类 |

| 5 | 宏碁(Acer) | 通信类 |

4.同类型知识

| 时间 | 类型 |

| 2023-05 | 天语W366刷机教程:解锁新性能,焕发手机第二春! |

| 2024-04 | 小米电视4A与4C:尺寸、画质、音效与性价比全面对比 |

| 2024-11 | 华为耳机:震撼音效,智能体验,重塑听觉盛宴! |

| 2024-09 | 2012智能手机排行榜前十名:经典机型回顾 |

| 2023-08 | 揭秘新笔记本电池损耗奥秘:如何延长电池寿命至极限 |

5.客户反馈

| 地区 | 反馈详细信息 |

| 鹤壁 | 维修店环境优雅,服务一流。 |

| 金坛 | 电脑维修后速度大幅提升。 |

| 运城 | 价格公道,服务质量高。 |

| 廊坊 | 技术人员耐心解答,态度好。 |

| 晋江 | 维修店环境优雅,服务一流。 |

京公网安备11000000000001号

京公网安备11000000000001号 京ICP备11000001号

京ICP备11000001号